Worries about new composite made airplane

Commercial airplane manufacturers have been using composite materials in transport airplane components for decades. But since 2011, new large transport airplane build mostly in composite have started commercial service. This is the case of the Boeing 787, and later the Airbus A350. Some industry observers have raised concerns about the state of the science underpinning the expanded use of composite materials in commercial transport category airplanes and Aviation Authorities’ (FAA and EASA) preparedness for this transition. European and US Aviation Authorities are taking actions to address safety-related concerns linked to the use of composite structure, and the GAO (Government Accountability Office) has issue a report in October 2011 to raise its concerns.

1 - Increasing use of composite in commercial airplane

Composite materials in transport airplane components are being used for decades. Prior to the mid-1980s, airplane manufacturers used composite materials in transport category airplanes in secondary structures (e.g., wing edges) and control surfaces. In 1988, Airbus introduced the A320, the first airplane in production with an all-composite tail section and, in 1995, the Boeing Company introduced the Boeing 777, also with a composite tail section.

Composite materials used in commercial airplanes typically are produced by combining layers of carbon or glass fibers with epoxy.

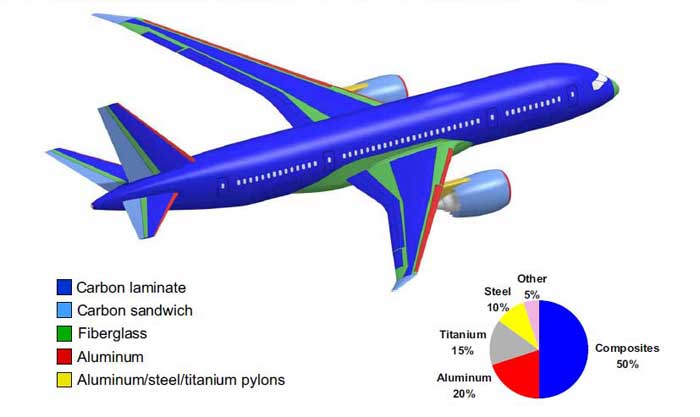

In recent years, manufacturers have expanded the use of composites to the fuselage and wings because these materials are typically lighter and more resistant to corrosion than are the metallic materials that have traditionally been used in airplanes.

The Boeing 787 is the first mostly composite large transport airplane in commercial service. The Boeing 787 is about 50 percent composite by weight (excluding the engines). It will carry 210-290 passengers on routes of 7650 NM to 8500 NM.

It will be followed soon by the Airbus A350, having composite material roughly in the same proportion as its Boeing competitor. The A350 Family provides true long-range capability of flying up to 8500 NM, with seating capacities from 250 to 400-plus passengers.

2 - Who is responsible for the safety of composite structure

The responsibility of the safety of an airplane, and subsequently of the safety of composite structure, is shared between three parties:

- The Airworthiness Authorities (e.g: FAA in US, EASA in Europe) are responsible for setting the certification standard and certifying that the airplane manufacturers and parts suppliers meet their standards. They also conduct periodic inspections of manufacturing facilities to ensure continued compliance with regulations, and oversee airplane repair facilities to ensure they follow the proper maintenance and training procedures.

- The airplane manufacturers are responsible for showing compliance with those regulations and building safe airplanes. They are also developing airplane maintenance programs and repair manuals and provide requested on-site technical assistance.

- The operators are responsible for operating airplane according to Airworthiness Authority rules and the manufacturer approved manuals. This includes performing adequate maintenance action when appropriate. Airplane operators also help maintaining the airworthiness of their airplane fleets by tracking their airplanes’ service history and reporting relevant repair and incident data to Authorities and the manufacturers.

3 - Safety concerns with composite structure

Some concerns have been raised related to the use of large proportion of composite on an airplane structure. These concerns mainly originated from the state of the science underpinning the expanded use of composite materials in commercial transport category airplanes, and the lack of experience with such design. While the GAO did not make any recommendations, it found four safety-related concerns:

- The first concern is the limited information on the behavior of composite airframe structures. These concerns focus on how composite airframe structures behave when damaged and as they age. These concerns are partly attributable to the limited in-service experience with composite materials used in the airframe structures of commercial airplanes and, therefore, less information is available on the behavior of these materials than on the behavior of metal. Designers rely on models to predict the behavior of composites part.

- The GAO also found challenges related to the detection of damage in composite materials and related to the unique properties of composite materials. "Impact damage to composite structures is unique in that it may not be visible or may be barely visible, making it more difficult for a repair technician or aviation worker to detect than damage to metallic structures," the GAO said. “Making a repair is also a concern partly because composite repairs are more susceptible to human error than metal repairs since the quality of a composite repair is highly dependent on the process used.”. Experience have already shown that aircraft can be grounded several days for a repair on a composite structure, while a few hours would have been needed on a metallic part. This can be a severe drawback particularly because of the frequent damages done on aircraft by ground handling operations.

- In addition, there is limited standardisation of composite materials and repair techniques, compared to metal materials and repairs. This is partly due to business proprietary practices and the "relative immaturity" of the use of composite materials in aircraft structures. "A repair technician could confuse materials or processes, which may result in improper repairs," the GAO said. This can also have negative economic impact for airlines and repair stations because a repair facility might have to keep a large stock of repair materials and parts in house. Also, composite materials generally need to be stored at a specific temperature, and the materials also have shelf lives (i.e., expiration dates).

- The organisation also identified concerns related to the level of training and awareness of workers handling composites. "Airplane repair technicians and designees that have worked with metal materials for decades generally may not be as familiar with composite materials, whose application in airplanes is relatively recent and whose unique characteristics are associated with technical challenges." it said.

Many efforts are ongoing or planned by the Airworthiness Authorities to help address these areas of safety-related concerns. Efforts to address these concerns include issuing new or modified guidance and policy, conducting research, developing and implementing training and collaborating with industry stakeholders.

However, “It is too early to fully assess the adequacy of [Authorities] and industry efforts to address safety-related concerns and to build sufficient capacity to handle and oversee composite maintenance and repair, given that composite airframe structures in currently in-service airplanes are mostly limited to the secondary structures” says the GAO.

Finally, “Several experts reiterated that while not every risk can be known, the use of composites is not revolutionary; rather, it is a new application of technology that has a history in military and general aviation applications.” says the GAO.

4 - Conclusion

Composite technology is not a revolution in aviation, and it was already used in the past for some aircraft parts. However, since 2011, large commercial plane build mostly in composite have started commercial service, and this creates many safety concerns in the aviation community, mainly because of the lack of experience with such design and the huge differences between the safety-proven metal and the composite.

Also, the adaptation of operational and maintenance procedures to fit with composite particularities may have a negative economic impact.

Commercial aviation has grown in history thanks to successive jumps toward unknown areas. At each jump, many questions and worries arose, we eventually made the necessary progress, suited to the new technology and made it safe. Sadly, many accidents also happened further to these jumps, and this was the price to pay.

Large commercial plane build mostly in composite is another jump, and this is probably the future of aviation as it allows designing lighter, more efficient and greener aircraft. But today, an airplane accident due to the use of composite is not an option, and the public opinion cannot accept to pay such a price anymore.

Written in October 2011